Dry Ice Cleaning for Industrial Electronics and Components

“Cleaning plays a decisive role in the repair and maintenance of automation technology. Influences of the production environment, dust, temperature and humidity have a negative effect on the condition and functionality of electronic components, which can lead to failure of the assembly at the customer and in the worst case result in a production plant downtime.”

– Stefan Berger, head of department drive technology at Eichler

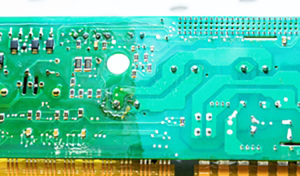

In Germany, Eichler GmbH is a leading industrial electronics service center. Eichler has unique knowledge and experience in the repair of automation technology components in the fields of HMI, control systems, drive technology and robotics. For this equipment, the repairs are done at the component level using the latest analysis, cleaning and repair tools. Repairing components requires the stripping of protective-lacquer assemblies and circuit boards. Heavily soiled fan and housing components must be cleaned until they are considered spotless.

Cleaning may need to be undertaken several times a day, using manual methods, which is time consuming and often provides incomplete results. The cleaning of electrical components takes a significant amount of time, diligence and care. It can often be a time consuming process as it involves careful disassembly and then manual hand washing. This was not an efficient method of cleaning, and so a more effective cleaning solution had to be implemented.

For these reasons, Dry Ice Cleaning was an ideal solution as it cleans to a superior standard, will not damage delicate electrical components and requires little to no disassembly.

For these reasons, Dry Ice Cleaning was an ideal solution as it cleans to a superior standard, will not damage delicate electrical components and requires little to no disassembly.

Non-abrasive

Dry Ice Cleaning is non-abrasive, and therefore will not damage delicate components or surfaces.

No Secondary Waste

Dry Ice sublimates (i.e. turns to a gas) when it comes into contact with the surface, and therefore no secondary waste is produced. This reduces the amount of time needed for cleanup and also costs associated with this and waste disposal.

Safe Process

Dry Ice Cleaning is a moisture free, non-conductive, dry process. Due to this, it is safe for use on sensitive and delicate electrical equipment. There is no water used in the process.

Superior Clean

Dry Ice Cleaning provides a highly accurate and superior quality clean which could be not achieved with a manual clean.

No Disassembly Required

Dry Ice Cleaning cleans without the need for tedious and time consuming disassembly.

User Friendly

Dry Ice Cleaning was considered user friendly and therefore it was readily accepted by employees and easily integrated into their previous processes. As there is no longer contact with harmful chemicals, the process is now safer for employees.

Environmentally responsible

As Dry Ice is reclaimed CO2, it is an environmentally sustainable process.

For more information on the capabilities of Dry Ice Cleaning or how it may be suitable for your business needs, contact us today.

This was first posted on www.coldjet.com