Dry Ice Cleaning is one of the most efficient and effective cleaning methods within the plastics and medical device sectors.

We sell Cold Jet's Dry Ice Blasting systems for cleaning, surface preparation and parts finishing that are designed with unrivalled innovation and unmatched performance.

Our Service offering includes:

- High quality dry ice pellets and blocks

- Machine sales and service

- Full Certificated training

- Nationwide service

Dry Ice Cleaning is a moisture-free, non-abrasive, non-conductive cleaning that will:

- Increase Yield - Improve part quality, more consistency, reduce part rejects, lower process variability, better surface finish.

- Increase Productivity - Increase mold uptime, extended production runs, unlock hidden manufacturing capacity.

- Extend Asset Life - Longer tool life, non-abrasive cleaning method.

- Reduce Operating Costs - Reduced manpower, faster mold cleans, more often, and cheaper.

- Increased Environmental Quality - Zero Waste, Elimination of solvents and waste cleaning by-products, elimination of pollution management.

Cold Jet are the Global leaders in manufacturers (OEM) of Dry Ice Cleaning technology with over 30 years of experience and hold the original patent on dry ice blasting equipment.

Polar IceTech are Dry Ice Blasting Specialists and are the official partners with ColdJet in Ireland and Northern Ireland.

Dry Ice Blasting Equipment

Dry Ice Blasting systems for cleaning, surface preparation and parts finishing. Designed with unrivaled innovation and unmatched performance.

Integrated Blast Systems

Combining multiple blasting systems and dry ice production facilities for continuous or fully automated use. Custom engineered to meet specific requirements.

Service & Support

ColdJet's Irish customer support team is available to answer your questions. Contact us: email info@polaricetech.ie or phone ROI: +353 21 4232020 NI/UK: +44 (0)28 95680037.

Cold Jet in Ireland

- Operating since 1986

- Hold the original patent on dry ice blasting (US Patent 4,617,064)

- Hold over 20 technology patents

- Hold over 100 global patents

- Have the largest market share

- Have the largest install base

- Have the largest dedicated engineering staff

- Have a state-of-the-art Manufacturing facility

Proudly serving hundreds of companies across the island of Ireland since 2005.

Polar IceTech offer sales and service to multiple sectors integrating state of the art integrated systems as well as one of machine sales.

Polar IceTech have a unique service contract with large global brands which include:

Proudly serving hundreds of companies across the island of Ireland since 2005.

Polar IceTech offer sales and service to multiple sectors integrating state of the art integrated systems as well as one of machine sales.

Polar IceTech have a unique service contract with large global brands which include:

- 24hr telephone support

- Replacement machine within 48 hours if we cant fix it on site

- Annual servicing

- Certified Training

No-one in Ireland knows more about Dry Ice Cleaning than Polar IceTech. Award-winning Dry Ice Blasting Specialists, Polar IceTech work with some of Ireland's leading brands throughout the island of Ireland.

No-one in Ireland knows more about Dry Ice Cleaning than Polar IceTech. Award-winning Dry Ice Blasting Specialists, Polar IceTech work with some of Ireland's leading brands throughout the island of Ireland.

- 12+ years of experience working with

- Main distributor of ColdJet for Northern Ireland & Republic of Ireland

- Dedicated sales, service and engineering staff

- Equipment sales into some of Ireland's leading brands

- Offering Contract Cleaning Services to multiple industries

- Expanding every year

Polar IceTech was the first company to introduce the concept of industrial dry ice blasting into Ireland in 1996. Since then we have amassed a wealth of knowledge & experience in all aspects of Dry Ice Blast cleaning across many industries.

Polar IceTech are committed to remaining the leader in Dry Ice Blast Cleaning solutions and are both competent & capable of completing the proposed scope of work within any plant while meeting & exceeding the required standards set out by our clients.

See more about our work at Polar IceTech on our website

Clean mold cavities and vents are a major concern for plastic part manufacturers in maintaining today’s high quality standards. The build-up of unwanted surface residues from either the resin additive off-gases or the use of mold releases can create various problems, ranging from product release (“knock out”) to inferior product quality and possible damage to tools. Flash, burn and short shots on the product caused by clogged vents also creates challenges for manufacturers.

Clean mold cavities and vents are a major concern for plastic part manufacturers in maintaining today’s high quality standards. The build-up of unwanted surface residues from either the resin additive off-gases or the use of mold releases can create various problems, ranging from product release (“knock out”) to inferior product quality and possible damage to tools. Flash, burn and short shots on the product caused by clogged vents also creates challenges for manufacturers.

Cold Jet dry ice blasting removes the waxy, paraffin build-up that can lead to blemishes (orange peel effect) on the bottles while the molds are hot and on-line.

The manufacturing of a polyurethane foam product used in sound dampening for autos and vans leaves the manufacturer with molds coated with an isocyanate/wax mold release. Mold release build-up eventually causes "knock out" problems, and, in extreme cases, the wax release agent becomes encased in the polyurethane foam product, making the product unusable.

With Cold Jet dry ice blasting, molds are cleaned in only 15 to 20 minutes and the cavities are more thoroughly cleaned = 20 times as many molds can be cleaned with dry ice blasting versus conventional methods. Production up time is increased by 100 to 120 hours and maintenance crews are now free to attend to other duties.

Cold Jet dry ice blasting can clean entire blow and injection mold cavities completely and effectively. Many leading blow molding bottle manufacturers have discovered that dry ice blasting systems cut their daily mold cleaning time by about 80% simply by cleaning molds hot and in place. Today, even the back 1/3 of the blow-mold surface and the entire deep-cavity injection molds used to make test-tube shaped slugs are cleaned by dry ice blasting whereas it used to have to be cleaned by hand.

Today's medical device manufacturers are well-familiar with micromolding of precision (high-tolerance) parts - and all the problems associated with it. From the production of catheter tips to surgical device handles to surgical stents, clean manufacturing equipment is paramount.

Today's medical device manufacturers are well-familiar with micromolding of precision (high-tolerance) parts - and all the problems associated with it. From the production of catheter tips to surgical device handles to surgical stents, clean manufacturing equipment is paramount.

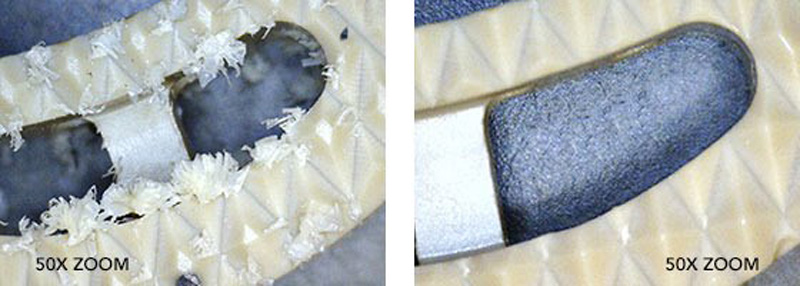

Keeping micro-cavities in production molds clean (as well as cleaning the small, deep, complex geometry of micro tools) is a critical concern when manufacturing very high tolerance medical device parts. In addition, cleaning the clamping devices (used during the fabrication process) and removing parting line flash (deflashing) or material burrs (deburring) from final products are equally significant manufacturing issues.

Unlike micro-sandblasting (a common technique used for removing buildup from clamps holding parts in place during manufacture) dry ice blast cleaning does not damage or destroy the clamps - eliminating high tooling replacement costs. Dry ice blast cleaning also requires no secondary waste cleanup from grit media or solvent use, and dry ice blasting systems generally eliminate the need to disassemble tooling during cleaning. All of these savings contribute to not only reduced cleaning costs, but also decreased overall downtime and reduced product scrap rates.

Precision dry ice blast cleaning is the perfect way to improve your medical device manufacturing processes.